How Refrigeration Systems Waste Energy:

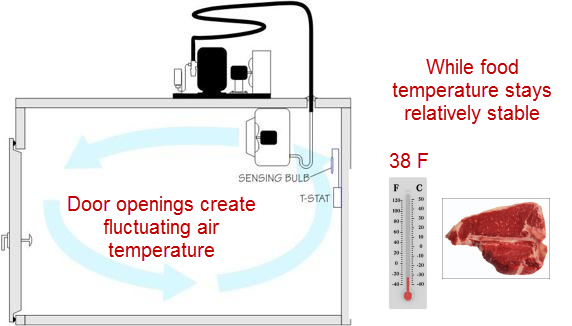

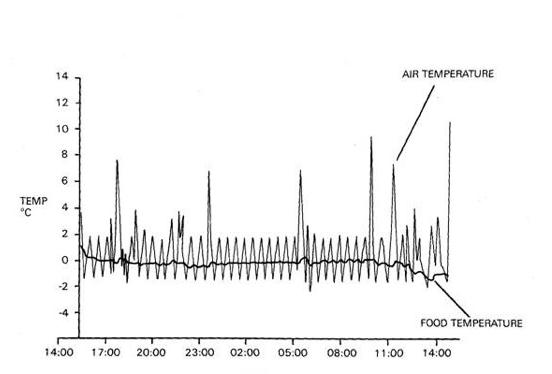

Refrigeration systems work in a series of on/off cycles measuring the air in and around the products they cool. All systems will start and stop to maintain a pre-set storage temperature. Refrigeration thermostats usually monitor circulating air temperature in order to decide when to switch on and off. Circulating air temperature tends to rise quicker than food temperature when refrigerator doors are opened and closed. Heat runs to cold and when the refrigerator door is opened. Warmer air migrates into the cold storage space, triggering thermostat to switch compressor on. As a result, refrigeration systems work harder than necessary to maintain products at the temperature prescribed by the thermostat. Product temperatures do not rise as quickly as air because of their stored thermal energy. The refrigeration system is treating air temperature and not reacting to food temperatures, which uses more energy than necessary with frequent starts and stops.

Refrigeration systems typically produce a minimum of 12 on/off cycles per hour, and in some open display cases, 20 cycles per hour. This leads to excessive kWh consumption and undue wear and tear on the equipment. The results are higher energy bills and shorter equipment life spans. Both conditions leave an exaggerated impact on the environment through higher kWh consumption and the disposition implication of refrigeration systems with shorter life spans.

ACTUAL AIR TEMPERATURE RECORD OF A WALK-IN CHILLER

Example – frequent door openings cause fluctuating air temperature which increases refrigeration compressor ‘on and off’ cycles and increases energy usage.

WHAT IS AN ENDOCUBE AND HOW IT WORKS:

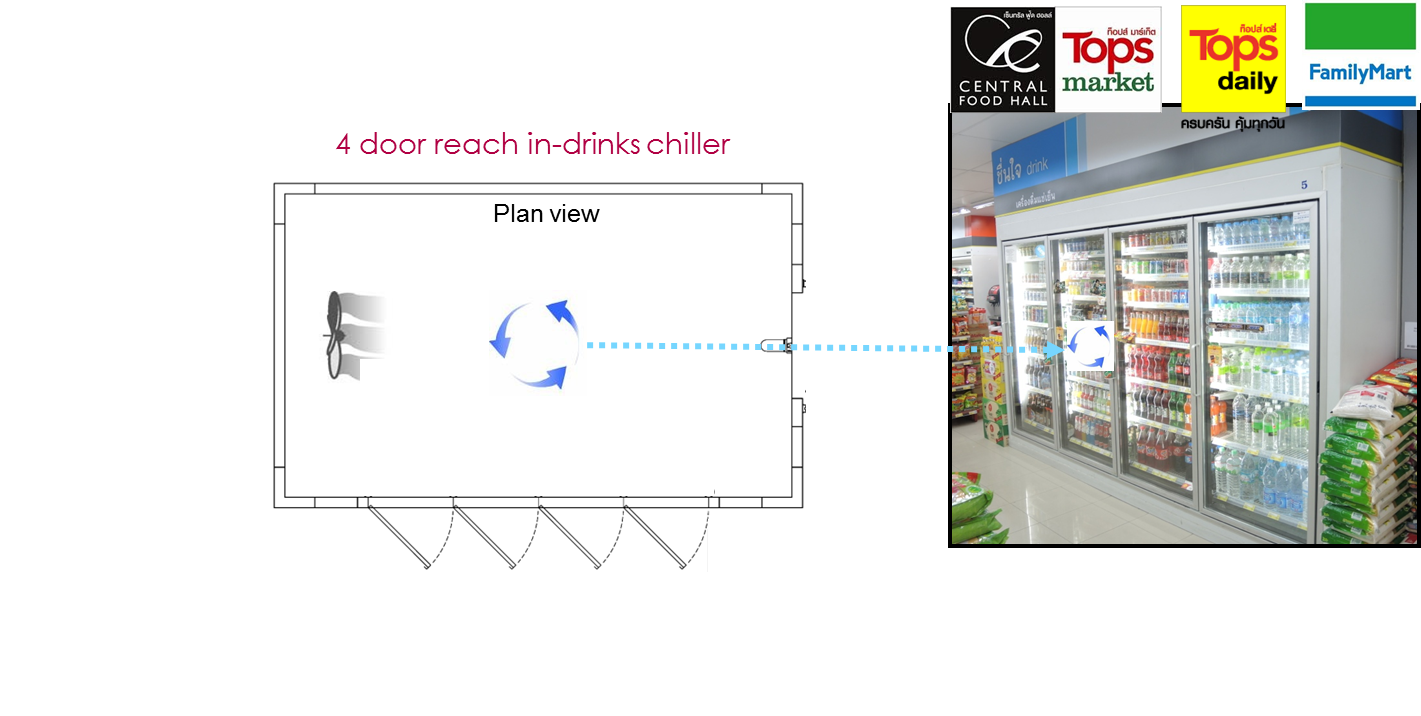

EndoCube is the first patented product to change the way we approach refrigeration temperature control. EndoCube is a patented blend of microystalline food grade wax property that creates an air barrier around thermostat probe. NSF International Certification under protocol 235, has proven EndoCube to mimic food and beverage properties. Current practice uses volatile air temperature to trigger refrigeration demand. After EndoCube installation, the refrigeration system reacts to product temperature not air temperature. Product temperature is not as volatile as air, and product has built up thermal inertia stored within. Product temperature, now represented by EndoCube, is controlling the refrigeration system, switching it on and off when product temperature requires it, not fluctuating air temperature.

KEY BENEFITS:

The EndoCube provides the thermostat with product temperature instead of surrounding air temperature, a far more accurate measurement. The use of an accurate and stable product temperature causes the compressor to run fewer, but longer cycles. The longer cycles allow refrigerated food and beverage to cool for a longer period of time storing thermal inertia. EndoCube installations provides a far more efficient cooling system by:

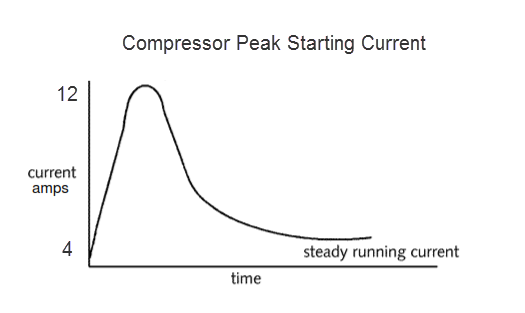

1. Creates longer on and off refrigeration cycles. Longer off cycles allows pressure equalization between high and low pressure parts within refrigeration system, allowing for “softer” starts and obtains maximum efficiency far quicker. Longer on cycles create a higher efficiency of the refrigeration cycle, much like a car traveling 60 mph on a freeway. It gets better fuel mileage than one in city traffic starting and stopping.

2. Reduces kWh consumption between 12% to 22% and sometimes more.

3. Reduces compressor starts by 50% and sometimes more. Start up of a refrigerator compressor uses 3 times more energy (i.e. start up uses 12 amps and running uses 4 amps).

4. Starting components used on refrigeration equipment have an engineered life span, so the less maximum power use of these components will extend the reliability and reduce refrigeration failure pro-rata.

5. Defrost cycles can be reduced in some cases, further reducing kWh consumption. Defrost cycles induce heat to eliminate condensation frost. This defrost heat has to be removed to return to a set storage temperature.